The premature deterioration of reinforced concrete structures due to corrosion is a major concern for asset owners. Thankfully, with expert advice and effective corrosion control, concrete structures can be preserved for generations.

Fosroc ANZ is proud to be the Australian distributor of Vector Corrosion Technologies' innovative corrosion control products. Recognised world wide for their proven, long-term performance, Vector products have been tested for use with Fosroc's Renderoc range of concrete repair mortars and shown to deliver outstanding results.

A shared commitment to long-lasting structures

Both members of the Concrete Preservation Alliance, Fosroc and Vector have a long-standing relationship and share a commitment to ensuring buildings are constructed to last.

As Hamid Khan, Fosroc ANZ's Product Segment Specialist Concrete Repairs and Grouts points out, concrete structures should exhibit a longer service life after proper concrete remediation.

"With better corrosion management, many of our structures would last significantly longer and require far less maintenance," he says.

Innovative corrosion control

Andrew Dickinson, Vector Corrosion Technologies' Business Development Manager for the Oceania region concurs, explaining that all industries face unique challenges in preserving concrete assets, but the one common factor is corrosion.

"Regardless of whether you're working on a city building, a bridge, a power plant, or a Port facility you'll need to protect against corrosion," he says.

From remediating existing issues in structural concrete to proactively protecting against corrosion in new structures, finding the right corrosion control solution is paramount.

Fosroc provides clients with access to a range of innovative Vector corrosion control technologies, including:

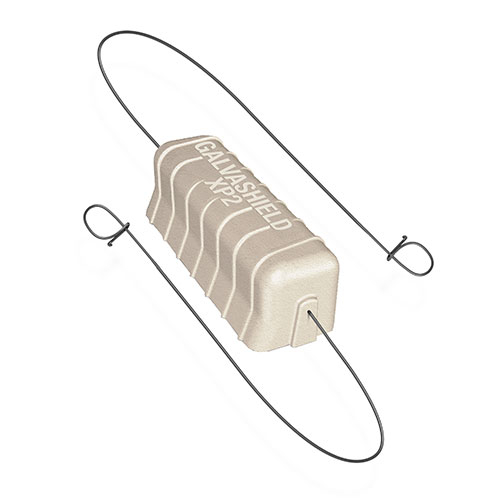

• Discrete and distributed galvanic anodes

• Fusion anodes

• Impressed current anodes

Galvanic anodes - a set and forget solution

Galvanic anode technology protects reinforcing steel through the use of sacrificial anodes.

According to Hamid, galvanic cathodic protection in reinforced concrete structures is becoming increasingly popular due to its easy application and low maintenance.

"The advantage of galvanic anodes is that no ongoing monitoring is required. It's a set and forget type of solution," he explains.

He points out that the wide range of galvanic anode systems available provides greater choice when selecting the right solution for a particular project.

Vector galvanic anode products available through Fosroc include:

Impressed current anodes - lasting protection with ongoing monitoring and maintenance

Typically used for larger structures, impressed current anodes provide protection through externally powered anodes.

Andrew explains that these are long-lasting systems that provide high levels of protection and service lifes, but require ongoing monitoring and maintenance.

Vector impressed current anode products available through Fosroc include:

Fusion anodes - long term, maintenance-free protection

Fusion anodes combine the long-lasting power of impressed current anodes with the maintenance-free performance of galvanic anodes.

"The unique and innovative aspect of fusion anodes," Hamid explains, "is that they do not require complex wiring or an external DC power supply.”

The Vector fusion anode products available through Fosroc include:

Benefits of corrosion control technologies

According to Andrew, corrosion control benefits more than just the bottom line.

"Extending the service life of concrete structures through effective corrosion control can be one of the most economical and sustainable activities that we can pursue in the construction industry," Andrew explains.

According to the Concrete Preservation Alliance, it's estimated that for every 10,000 cubic yard (approximately 7600 cubic metres) of concrete that is preserved:

- 20,000 tons of solid waste is kept out of landfill

- 5,468 tons of CO2 production is avoided

- 20,000 tons of natural resources is saved

- 250,000 gallons of potable water is saved

Combined expertise for a tailored solution

Corrosion management in concrete is a highly specialised field requiring extensive technical knowledge.

Through the combined expertise of Fosroc and Vector Corrosion Technologies, asset owners, engineers and builders can access expert advice and guidance on the design, installation, and maintenance of corrosion control solutions.

Find out more

- Find Vector products on our Products page.

- Download the Vector Corrosion Control Technologies brochure.

- Download Fosroc ANZ's Concrete Repair Solutions brochure.

- Access a range of resources on concrete preservation, concrete repair and concrete restoration on the Concrete Preservation Alliance website.

Visit the Vector Corrosion Technologies website